manufacturing: adaptive choreography

KidRunner-Social Ergonomics

S/U/M joined KidRunner when the concept existed as vision rather than system. The project demanded design development under constant constraint—limited time, limited capital, and ambitions that exceeded both. S/U/M established a process that could keep moving despite those limits: a choreography of making, testing, and storytelling that maintained momentum when production and funding slowed.

KidRunner emerged from motion itself — design, testing, and storytelling had to run in sync.

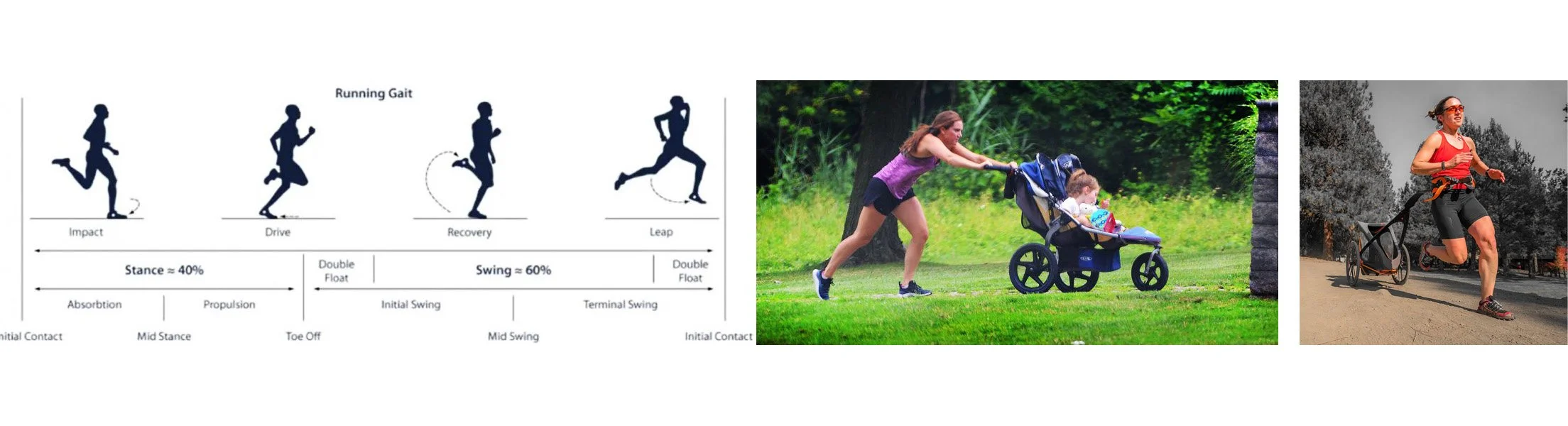

KidRunner began with a contradiction between motion and care. Pushing breaks rhythm; pulling breaks trust. The question was whether design could close that gap.

S/U/M was brought in to align performance, safety, and social acceptance—to engineer a product that would let running and parenting move as one act.

Vision Without Roadmap

KidRunner approached S/U/M with a clear vision but no infrastructure to realize it. The stroller industry had stalled for decades; performance design and childcare lived in separate worlds. S/U/M’s first task was to translate ambition into a working roadmap—an adaptive framework where each prototype had to justify its cost by advancing performance, manufacturability, and public imagination simultaneously.

Process in Motion — Precision Meets Improvisation

Process — Bridging Onshore and Offshore

The next challenge was translation: how to move from shop-built invention to offshore precision without losing intent.

S/U/M structured the build-10 phase as that bridge. Offshore partners handled what required industrial tooling—carbon shells, machined fittings, and composite subframes—while the studio built what was still unresolved: harness geometry, assembly sequence, and user ergonomics.

Each prototype joined the knowable with the yet-to-be-learned. The factory made what could be defined; the studio explored what still needed discovery. This overlap let both sides calibrate to each other—offshore learning nuance, onshore learning scale—until a shared language of tolerance and assembly emerged.

To test that alignment under real conditions, S/U/M engaged a small group of elite runner-parents. Their feedback on stride mechanics, balance, and handling shaped the design as much as factory data did. The build-10 phase became both engineering bridge and social experiment, where manufacturability and experience were refined side by side. Those trials set the stage for the final step—validation beyond the studio.

Validation —stress testing the system

Once the prototypes left S/U/M’s hands, testing shifted from collaboration to proof.

The truest measure came through use, not metrics.

World-champion trail runner Max King won his hometown 5 K pushing his daughter in a KidRunner—demonstrating that performance and parenting could share the same stride. At another scale, adventurer Jan Caspar began training for an around-the-world run, using KidRunner as a self-supported supply vessel.

Each of these independent efforts returned data no controlled trial could simulate: durability, handling, and social ergonomics measured through distance, weather, and public visibility. Validation closed the loop the project had built from the start—design, manufacture, and human experience feeding each other until proof replaced speculation.

Designing in Public — Visibility as R&D

Momentum wasn’t just mechanical; it was social. Field tests, photography, investor pitches, even Shark Tank—each functioned as a design event disguised as exposure.

Visibility became feedback. The prototypes were not only judged but observed, revealing how trust and motion translated in public.

Those appearances produced the project’s largest turning point.

When KidRunner reached a national audience, its engineering impressed but its price stalled the conversation. The market wasn’t questioning performance—it was questioning relevance. How could a high-performance stroller command that cost for an activity most parents endured rather than desired?

For S/U/M and KidRunner, this moment became the necessary correction—a public reckoning with value itself. The response wasn’t retreat but expansion. The studio helped reframe the product as a platform, adding cycling and skiing modes to extend both use and meaning. What had begun as a niche running device became a modular system for movement—a design built to earn its value through adaptability.

Public visibility exposed the problem; design answered it.

Resonance — Performance with Care

KidRunner’s launch demonstrated the effectiveness of S/U/M’s adaptive workflow. The studio’s role extended from early prototyping through offshore integration, ensuring that each stage—engineering, fabrication, and testing—aligned with cost, performance, and user experience objectives. The completed product verified the method rather than the myth: disciplined process yields dependable results.