rapid-type

Prefabrication promised efficiency. Architecture’s industrial future was meant to arrive in parts, assembled quickly, saving time and cost. It didn’t. The irony was that the most successful prefabricated structures weren’t buildings at all—they were food trucks.

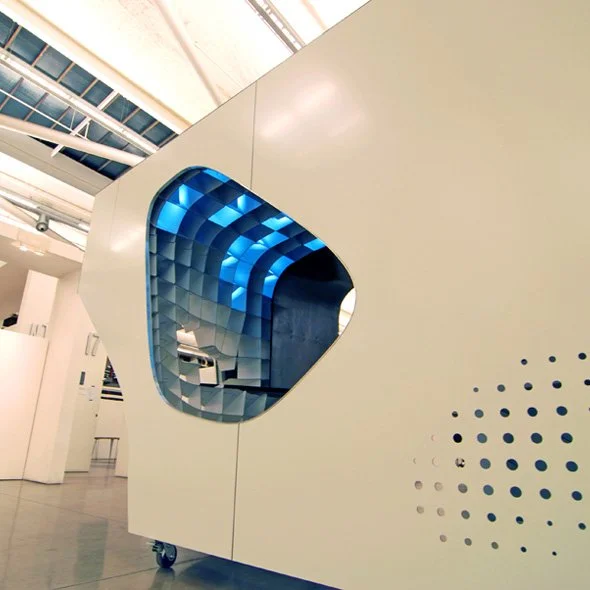

Rapid Type turned that contradiction into a design agenda. Co-taught with Kory Bieg of OTA+, the project re-imagined prefabrication not as static enclosure but as mobile architecture. Using CNC fabrication and a donated supply of Alpolic aluminum composite from Mitsubishi Plastics, the prototype tested the material’s full range—cut, folded, and joined to form a compact, deployable coffee pod.

Conceived for the slow-drip coffee movement, Rapid Type fused building precision with street-level immediacy: a high-design object with full mobility and rapid assembly. Prefabrication escaped the factory floor and found new relevance in motion—architecture that serves, circulates, and connects directly with its public.

Credits

Design collaboration: S/U/M (Andre Caradec) and OTA+ (Kory Bieg)

Material sponsor: Mitsubishi Plastics, Inc. (Alpolic)

Fabrication: CNC aluminum composite construction